CNC Turning Lathe CK6140

Description

Reviews

CK6140 Key Attributes

Industry-Specific Attributes

| type | Horizontal |

|---|---|

| max. length of workpiece (mm) | 750, 1000, 1500, 2000, 3000, 4000, 5000, 6000 |

- Taiwan, Japan precision components

- Professional after-sales service

- High production efficiency

| Parameters | Unit | CK6140 | CK6150 | CK6163 |

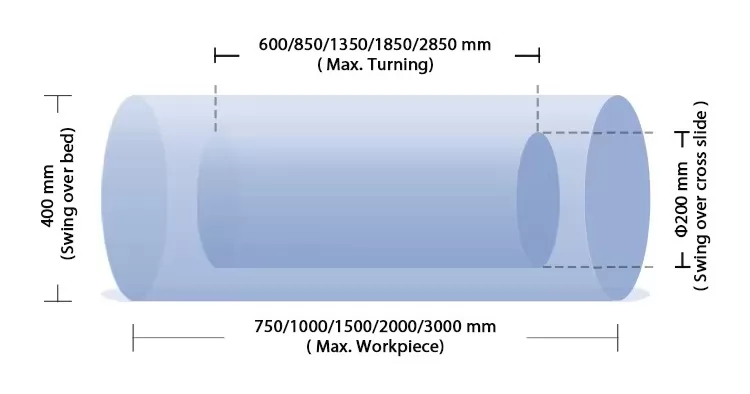

| Max dia.swing over bed | mm | 400 | 500 | 630 |

| Max dia.swing over cross slide | mm | 200 | 300 | 350 |

| Max. workpiece length | mm | 750/1000/1500/2000/3000 ... | ||

| Max. turning length | mm | 600/850/1350/1850/2850 ... | ||

| Bed width | mm | 360 | 400 | 550 |

| Spindle bore | mm | 52 | 82 | 105 |

| Spindle speed | rpm | 65-1600 | 65-1600 | 20-800 |

| X rapid traverse | m/min | 4000 | 4000 | 4000 |

| Z rapid traverse | m/min | 6000 | 6000 | 6000 |

| X-axis travel | mm | 210 | 270 | 330 |

| Z-axis travel | mm | 600/850/1350/1850/2850 ... | ||

| X/Z-axis positioning accuracy | mm | 0.02 | 0.02 | 0.02 |

| X/Z axis repeat positioning accuracy | mm | 0.01 | 0.01 | 0.01 |

| Main motor power | Kw | 5.5 | 7.5 | 11 |

| Tailstock sleeve diameter | mm | 75 | 75 | 100 |

| Tailstock sleeve travel | mm | 150 | 150 | 250 |

| Tailstock sleeve taper hole taper | / | MT5 | MT5 | MT5 |

| Machine weight | KG | 2000 | 2500 | 5000 |

| Dimensions L*W*H | mm | 2550*1500*1550 | 2670*1600*1650 | 3650*1880*1880 |

CK series CNC horizontal lathe with high precision, large power and high rigidity. the main components and structure have optimized design, can process shaft, plate, set, contour surface, and screw type artifacts.

GSK980TDC or FANUC 0i-mate CNC system and full digital ac servo system. X, Z axis adopts half closed loop control, ball screw is C3 level precision ball screw and electrical components use imported or domestic well-known brands, meeting the CE or domestic 3C certification.

Domestic well-known brand vertical four station CNC tool post, optional six-station or eight station horizontal electric tool post, with high positioning accuracy, high strength, good seismic performance.

The strict machine inspection will be done before out of factory. Each machine adopts laser interferometer to detect the X, Z axis positioning accuracy and repeat positioning accuracy, to ensure the stable accuracy of machine tool.